Mineral resources

The Kufner Group is a leading producer of stone materials in the region, boasting a long tradition, modern technologies and strategically positioned mineral deposits. Our production is based on high-quality limestone, dolomite and volcanic resources for use in construction, metallurgy, chemical industry and infrastructure.

Our deposits and capacities

Strategic quarry sites, long-term concessions and development of new exploration areas ensure long-term access to the reserves of mineral resources for top quality dolomite, limestone, diabase and basalt types of technical- building stone while also paving the way for Kufner Group’s long-term business sustainability.

- Location: Sirač, Daruvar - EP Čelina, EP Gusti rastik, IP Čelina 2,

IP Gusti rastik 1 - Annual capacity: 2.5 million tonnes

More than 140 years of history, tradition and experience in the production of stone materials and lime. Production is based on high-quality limestone and dolomite resources, giving their final products exceptionally versatile mechanical and chemical properties.

They are the reason why Kamen Sirač d.d. products have found their use in the chemical industry, metallurgy, construction and infrastructure, with almost all major companies in those sectors being counted among the company’s key customers. Technical-building stone is extracted at the sites of two mineral deposits having a total annual production capacity of around 2.5 million tonnes.

- Location: Međurače, Petrinja - EP Međurače, IP Tišina

- Annual capacity: 801,000 tonnes

In operation since 1998, it has considerable potential for expanding concession rights thanks to rich reserves of stone material. After being merged with the Kufner Group in 2022, it has recorded high income and profit growth rates, contributing significantly to the growth and development of the Group's key business segment.

Taking into account the deposit’s natural position as well as substantial reserves, the proximity of the sales market and increasing demand stemming from infrastructure projects, it has significant potential for further growth. Technical-building stone for use mostly in road construction and civil engineering is extracted from the deposit, which has an annual production capacity of approximately 801,000 tonnes.

- Location: Bojna, Glina - EP Bojna

- Annual capacity: 280,000 tonnes

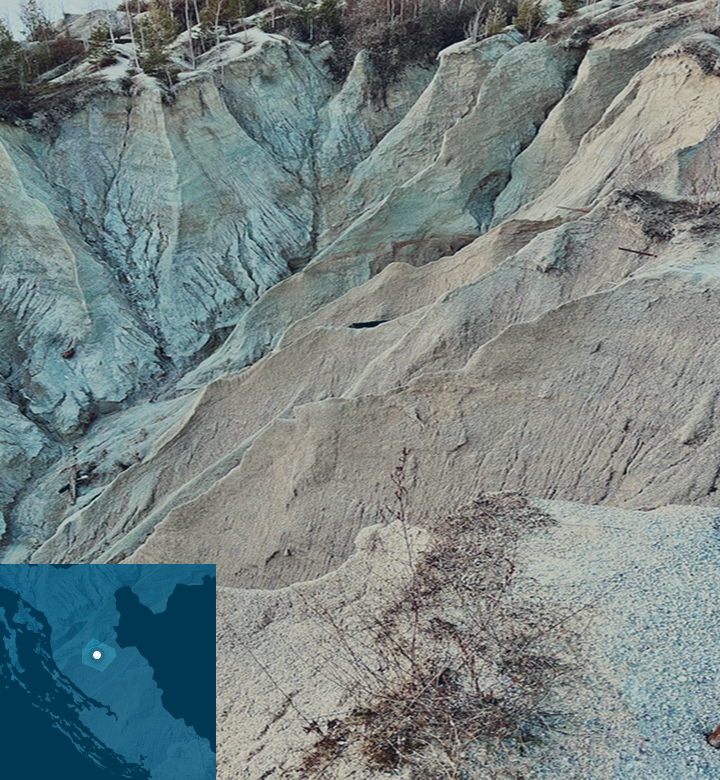

Focusing on the extraction and refinement of high-quality volcanic rock from the Bojna deposit near Glina. The Group integrated the Kamenolom Bojna quarry in April 2024, expanding its range of relatively limited and valuable stone materials of volcanic origin (diabase, basalt).

This lays the foundations for further growth in the mineral resources segment, especially for the railway and road infrastructure sector. The deposit, having an annual production capacity of around 280,000 tonnes, is used for the extraction of technical-building stone, finding its application in final layers during the construction, reconstruction and maintenance of all categories of road and railway infrastructure.

- Location: Perušić, Gospić - EP Tapanjska Glava

- Annual capacity: 268,500 tonnes

It focuses on the extraction and processing of mineral resources as well as their processing associated with the finalisation of stone and concrete products at the site of a limestone deposit in the vicinity of Perušić, near Gospić. The group took over Lika kamen d.o.o. in March 2024, securing a strategic position on key corridors of infrastructure construction, especially road maintenance projects, railway infrastructure construction and maintenance, and projects involving renewable energy sources.

Technical-building stone for use in civil engineering and road construction, railways and production of ready-mix concrete is extracted from the deposit, which has an annual production capacity of around 268,500 tonnes.

Production process

Our production process is based on modern technologies and strictly controlled procedures to ensure high quality and standardised products.

During the main season, between spring and autumn, the production of mineral resources takes place in two or three shifts, depending on the conditions at the deposit. Such organisation enables the annual production of almost 4 million tonnes with an optimum use of the capacity and human resources.

Extraction of mineral resources

The process begins with geological research and preparatory works, followed by the extraction itself. Depending on deposit characteristics, quarrying consists of machine drilling and blasting to fragment the rock into parts suitable for further processing.

01Transportation to the processing plant

Excavated material is transported to the processing plant by trucks. Efficient logistics within the quarry ensure a smooth flow, reducing operating expenses and increasing productivity.

02Refining and processing

- Crushing – primary and secondary processing of materials using crushers.

- Grinding – additional crushing to achieve the desired granulation.

- Sifting – separation and classification of particles into standardized fractions.

Quality control

To maintain consistent quality, modern technologies and laboratory analyses are used in every segment of production. Applying strict inspection processes and testing, we ensure that our products meet the requirements of the construction, chemical and metallurgical industries.

04